...

...

...

...

...

...

...

...

...

...

- The 30206a bearing is a type of tapered roller bearing that is designed to handle both radial and axial loads. Its unique design allows it to distribute the load evenly across the rollers, ensuring smooth and efficient operation. This makes it ideal for applications where reliability and performance are key factors.

- The outer diameter of the 6807 bearing is the distance between the two outer rings of the bearing. For this bearing, the outer diameter is 47 mm. This dimension affects the overall size of the bearing assembly and the clearance available around the shaft.

- In addition to these primary dimensions, other factors like the radial and axial clearance, load ratings, and material quality significantly impact the performance of a 16003 bearing. The radial clearance refers to the free space between the races and balls when no load is applied, allowing for thermal expansion during operation. The load ratings, including the radial and axial loads, define the maximum weight the bearing can withstand before degrading.

- The 32014 bearing is renowned for its outstanding performance characteristics. It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM)

It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM)

It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) 32014 bearing. Its load capacity is also impressive, with a maximum static load rating of 89,000 pounds and a dynamic load rating of 137,000 pounds. These figures make the 32014 bearing an excellent choice for high-performance machinery, such as pumps, turbines, and compressors.

32014 bearing. Its load capacity is also impressive, with a maximum static load rating of 89,000 pounds and a dynamic load rating of 137,000 pounds. These figures make the 32014 bearing an excellent choice for high-performance machinery, such as pumps, turbines, and compressors. - 3. Improved Reliability The precision tolerance and corrosion resistance of the 638 ZZ bearing ensure consistent performance and reliability in harsh environments. This feature enhances the overall integrity of machinery and equipment, reducing the risk of failures and downtime.

- One of the key advantages of the NN3020 bearing is its exceptional load capacity. It can withstand heavy loads with ease, making it an ideal choice for applications that require high stability and durability. Whether you're dealing with large machinery or demanding industrial processes, this bearing has the strength to get the job done.

- In conclusion, the 51406 thrust bearing is more than just a mechanical component; it is a symbol of precision, strength, and reliability. Its importance cannot be overstated, as it continues to play a vital role in pushing the boundaries of modern engineering. From heavy industry to cutting-edge technology, the 51406 thrust bearing stands as a testament to human innovation and the relentless pursuit of efficiency in machinery and equipment.

- The 6212 bearing can be either sealed or unsealed, depending on the application requirements. Sealed bearings are designed to prevent the ingress of contaminants and moisture, while unsealed bearings rely on adequate lubrication to maintain proper operation. Both types of bearings can be used in a variety of environments, but sealed bearings are generally recommended for applications where contamination is a concern.

- * Aerospace equipment

- 4

- 5. Maintenance-Free The 6205 bearing requires minimal maintenance due to its durable construction and low friction characteristics. Regular inspection and cleaning may be necessary to ensure optimal performance, but it does not require frequent replacement or costly maintenance procedures.

- The 6008 ball bearing is a deep groove ball bearing with a bore diameter of 40mm, an outer diameter of 68mm, and a width of 15mm. It is manufactured to precision specifications, ensuring smooth operation and long service life. The bearing is constructed with high-quality steel balls and raceways, allowing for low friction and efficient rotation.

- Bearing ID 80 OD 140 taper roller bearings are widely used in various industrial applications due to their excellent load capacity, high reliability, and long service life. These bearings consist of an inner ring, outer ring, tapered rollers, and a cage that keeps the rollers in position. In this article, we will provide a comprehensive guide to help you understand the specifications, selection, installation, maintenance, and troubleshooting of these bearings.

- Features and Benefits

- 3. Sealing The 6302RS bearing features a rubber seal on both sides, effectively preventing contaminants from entering the bearing and extending its service life. The seals also prevent the loss of lubricant, ensuring optimal performance even in harsh environments.

- Bearing 40*90*23 is a type of ball bearing commonly used in various industries due to its versatility and efficiency. This bearing is designed to support radial and axial loads simultaneously, making it ideal for applications where both types of forces are present.

- Each type of cylindrical roller bearing offers unique advantages, depending on the operational conditions and load requirements. Proper selection is crucial to ensure optimal performance, longevity, and efficiency in any mechanical system. Always consider factors like load capacity, speed, alignment, and maintenance needs when choosing the right cylindrical roller bearing for your application. With their versatility and robust design, cylindrical roller bearings continue to play a vital role in numerous industries, facilitating smooth and efficient operations.

- In conclusion, the 67048 bearing, with its robust design and versatile capabilities, is an essential element in modern industrial machinery. Its ability to minimize friction, support heavy loads, and operate at high speeds makes it a cornerstone in sectors ranging from automotive to aerospace. Despite its seemingly modest size, the 67048 bearing significantly contributes to the efficiency, reliability, and overall performance of complex systems, underscoring the importance of even the smallest components in engineering.

- 3. Inspection Regularly inspect the bearing for signs of wear, damage, or misalignment.

- The development and improvement of deep groove ball bearings have played a significant role in advancing machinery performance. By providing high load capacity, low friction, and versatility, these bearings have enabled the development of more efficient and reliable machinery. As technology continues to advance, we can expect to see further improvements in deep groove ball bearings, leading to even greater advances in machinery performance.

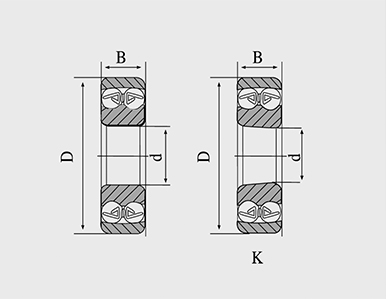

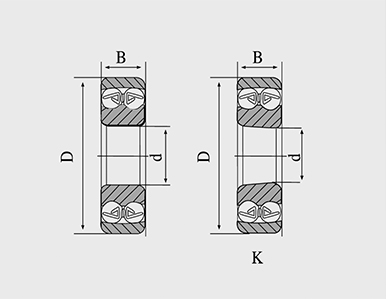

- The ID and OD define the physical space available for the bearing within the machinery. The width, or the B dimension, influences the bearing's load-bearing capacity and its suitability for compact designs. It's crucial to ensure that these dimensions align with the machinery's requirements.

- One of the key benefits of high precision deep groove ball bearings is their ability to maintain accurate alignment and rotation even under extreme conditions. This is achieved through the use of precision-ground inner and outer rings, as well as high-quality steel balls that are carefully spaced for optimal performance. The result is a bearing that can operate at high speeds without compromising on accuracy or durability.

- In the medical field, where accuracy and reliability are paramount, SRDG ball bearings find application in surgical instruments, diagnostic machines, and prosthetics. Their precise movement and low noise characteristics contribute significantly to the overall performance of these devices.

- Secondly, production efficiency and technology play a role. Advanced manufacturing processes, automation, and robotics can increase production speed, reduce labor costs, and improve product consistency, which could either lower or maintain competitive prices.

- 4

- These bearings are commonly used in industries like automotive, mining, construction, and power generation. Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity

Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity

Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life.

nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life. - The within the sequence is a URL encoding, representing a blank space in web addresses. It's a testament to how the internet translates human-readable content into machine-understandable formats. This conversion is pivotal for seamless navigation across the web, allowing us to access websites with spaces in their URLs.

- In terms of maintenance, the 6206 bearing is relatively low maintenance compared to other types of bearings. However, it is important to ensure that the bearing is properly lubricated to prevent premature wear and failure. Regular inspection and monitoring of the bearing's condition are also recommended to detect any signs of damage or wear early on.

- In conclusion, the 6005 2RS bearing is a testament to the importance of well-engineered components in modern industry. Its robust construction, combined with the protective rubber seals, makes it a reliable choice for various applications. As technology continues to advance, the demand for high-performance and durable bearings like the 6005 2RS will only increase, solidifying its position as an indispensable element in numerous industries. Whether it's precision machinery or everyday appliances, the 6005 2RS bearing is a testament to the power of innovative engineering in ensuring smooth operations and enhancing overall efficiency.

- The 16mm thrust bearing is commonly used in applications where there is a need to support high axial loads, such as in automotive transmissions, industrial gearboxes, and propeller shafts. Without a thrust bearing, these systems would experience excessive wear and premature failure due to the axial forces exerted on the rotating shafts.

- Conclusion

- 2. Speed The maximum speed at which the bearing can operate without causing excessive heat generation and wear is known as the maximum operating speed. The maximum operating speed depends on the bearing design, lubrication, and temperature rise.

- Another key aspect of snowboarding is understanding the importance of safety on the slopes

l68110. This includes wearing the appropriate gear, such as a helmet and goggles, as well as following the rules of the mountain and being aware of your surroundings at all times. By practicing good safety habits and being mindful of your actions on the slopes, you can help prevent accidents and injuries while enjoying your time on the mountain.

l68110. This includes wearing the appropriate gear, such as a helmet and goggles, as well as following the rules of the mountain and being aware of your surroundings at all times. By practicing good safety habits and being mindful of your actions on the slopes, you can help prevent accidents and injuries while enjoying your time on the mountain. - Furthermore, considering the operation within the realm of personal development, the smaller number might signify individual accomplishments, while the larger number represents life's challenges. The remainder then becomes a reflection of our perseverance, the evidence of our struggle to overcome obstacles and achieve our goals despite seemingly insurmountable odds.

- 2. High load capacity The 6005Z bearing is designed to withstand high radial and axial loads, making it suitable for applications that require heavy duty operation.

- Another popular material for deep groove ball bearings is ceramic. Ceramic materials offer several advantages over traditional metals, including lower weight, higher hardness, and improved resistance to heat and wear. These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount

These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount

These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount deep groove ball bearing material. However, ceramic materials are more brittle than metals and may not be suitable for applications involving heavy loads or shock absorption.

deep groove ball bearing material. However, ceramic materials are more brittle than metals and may not be suitable for applications involving heavy loads or shock absorption. - The choice of material is crucial for the performance of high temperature bearings. Chrome steel is a popular choice due to its good combination of strength, hardness, and toughness. Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C

Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C

Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C high temperature deep groove ball bearing.

high temperature deep groove ball bearing. - Another benefit of deep groove ball bearings is their durability

deep groove ball bearing meaning. The use of high-quality materials and precise manufacturing techniques ensures that these bearings can withstand heavy loads and operate reliably over extended periods. They are also relatively easy to install and maintain, contributing to their popularity in industrial settings.

deep groove ball bearing meaning. The use of high-quality materials and precise manufacturing techniques ensures that these bearings can withstand heavy loads and operate reliably over extended periods. They are also relatively easy to install and maintain, contributing to their popularity in industrial settings. - In conclusion, the enigma of 6300 2rsr is a fascinating journey through the world of cryptography. From the humble beginnings of RSA to the sophisticated algorithms that protect our most sensitive information today, this enigmatic sequence of characters represents a small but significant part of the ongoing struggle between cryptographers and hackers. As we continue to push the boundaries of what is possible with encryption, let us never forget the lessons learned from the pioneers who came before us.

- This bearing finds its application in a broad spectrum of industries, from automotive to aerospace, from home appliances to precision instruments

ball bearing 6000zz. In cars, they might be found in the wheel hub or the alternator; in electric motors, they support the rotor; in bicycles, they smooth out pedal rotation. The 6000ZZ's compactness and robustness make it ideal for use in compact electronic devices too, like fans and hard drives.

ball bearing 6000zz. In cars, they might be found in the wheel hub or the alternator; in electric motors, they support the rotor; in bicycles, they smooth out pedal rotation. The 6000ZZ's compactness and robustness make it ideal for use in compact electronic devices too, like fans and hard drives. - Despite their simplicity, cylindrical thrust bearings require proper maintenance to maintain peak performance. Lubrication is key to preventing metal-to-metal contact that could lead to galling or seizure. Regular checks for wear and tear, as well as timely replacement of damaged components, are essential practices that contribute to the overall reliability and longevity of machinery employing these bearings.

- The Impact of ZZ Bearings on the Machinery Industry

- Ball Bearing Size and Configuration: The size and arrangement of the balls within the bearing, as well as the number of balls, influence the bearing's load-carrying capacity. Larger bearings with more balls are generally capable of handling higher thrust loads.

- Secondly, the complexity of the design and manufacturing process contributes to the pricing. Tapered bearings require precise engineering, with each component - the cones, cups, and rollers - needing to be manufactured to exacting tolerances. This precision engineering, coupled with the need for rigorous quality control, increases the production cost, which is then reflected in the selling price.

- In addition to aiding in the selection process, the taper bearing ID and OD chart can also be a valuable resource for troubleshooting and maintenance

taper bearing id od chart. By referencing the chart, technicians can quickly identify the correct replacement bearing for a faulty or worn-out component. This can help minimize downtime and keep the system running smoothly. - Applications

- Design Innovation

They represent our presentation to the world, reflecting our personality and status They represent our presentation to the world, reflecting our personality and status

They represent our presentation to the world, reflecting our personality and status They represent our presentation to the world, reflecting our personality and status wash cloth. The act of washing clothes, therefore, becomes an expression of self-care and grooming.

wash cloth. The act of washing clothes, therefore, becomes an expression of self-care and grooming. It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM)

It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) It boasts a high speed rating, allowing it to operate at speeds up to 15000 revolutions per minute (RPM) 32014 bearing. Its load capacity is also impressive, with a maximum static load rating of 89,000 pounds and a dynamic load rating of 137,000 pounds. These figures make the 32014 bearing an excellent choice for high-performance machinery, such as pumps, turbines, and compressors.

32014 bearing. Its load capacity is also impressive, with a maximum static load rating of 89,000 pounds and a dynamic load rating of 137,000 pounds. These figures make the 32014 bearing an excellent choice for high-performance machinery, such as pumps, turbines, and compressors. Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity

Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life.

nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life. l68110. This includes wearing the appropriate gear, such as a helmet and goggles, as well as following the rules of the mountain and being aware of your surroundings at all times. By practicing good safety habits and being mindful of your actions on the slopes, you can help prevent accidents and injuries while enjoying your time on the mountain.

l68110. This includes wearing the appropriate gear, such as a helmet and goggles, as well as following the rules of the mountain and being aware of your surroundings at all times. By practicing good safety habits and being mindful of your actions on the slopes, you can help prevent accidents and injuries while enjoying your time on the mountain. These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount

These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount These properties make ceramic bearings ideal for high-speed applications where precision and longevity are paramount deep groove ball bearing material. However, ceramic materials are more brittle than metals and may not be suitable for applications involving heavy loads or shock absorption.

deep groove ball bearing material. However, ceramic materials are more brittle than metals and may not be suitable for applications involving heavy loads or shock absorption. Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C

Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C Stainless steel is also commonly used because it has excellent corrosion resistance and can withstand high temperatures up to 120°C high temperature deep groove ball bearing.

high temperature deep groove ball bearing. deep groove ball bearing meaning. The use of high-quality materials and precise manufacturing techniques ensures that these bearings can withstand heavy loads and operate reliably over extended periods. They are also relatively easy to install and maintain, contributing to their popularity in industrial settings.

deep groove ball bearing meaning. The use of high-quality materials and precise manufacturing techniques ensures that these bearings can withstand heavy loads and operate reliably over extended periods. They are also relatively easy to install and maintain, contributing to their popularity in industrial settings. ball bearing 6000zz. In cars, they might be found in the wheel hub or the alternator; in electric motors, they support the rotor; in bicycles, they smooth out pedal rotation. The 6000ZZ's compactness and robustness make it ideal for use in compact electronic devices too, like fans and hard drives.

ball bearing 6000zz. In cars, they might be found in the wheel hub or the alternator; in electric motors, they support the rotor; in bicycles, they smooth out pedal rotation. The 6000ZZ's compactness and robustness make it ideal for use in compact electronic devices too, like fans and hard drives.